Discover the Adaptability of Aluminum Castings: Vital Facts and Providers You Should Know

Light weight aluminum castings are increasingly identified for their versatility throughout various sectors. Their light-weight nature, corrosion resistance, and strength-to-weight proportion make them a recommended selection in many applications. From auto to aerospace, the adaptability of these spreadings is impressive. Yet, the approaches of production and the series of services readily available often go undetected. Comprehending these facets can considerably influence job end results and efficiency. What important truths and solutions should one consider when checking out light weight aluminum castings?

The Feature That Make Aluminum Castings Perfect for Various Industries

Aluminum spreadings have a distinct mix of homes that render them extremely appropriate for a large range of markets. Their light-weight nature is just one of one of the most significant advantages, permitting much easier handling and decreased transport expenses (Aluminum Foundry). Aluminum castings also display exceptional corrosion resistance, which lengthens the life-span of parts in tough settings. Additionally, they use excellent thermal and electric conductivity, making them suitable for applications calling for reliable heat dissipation or electrical links

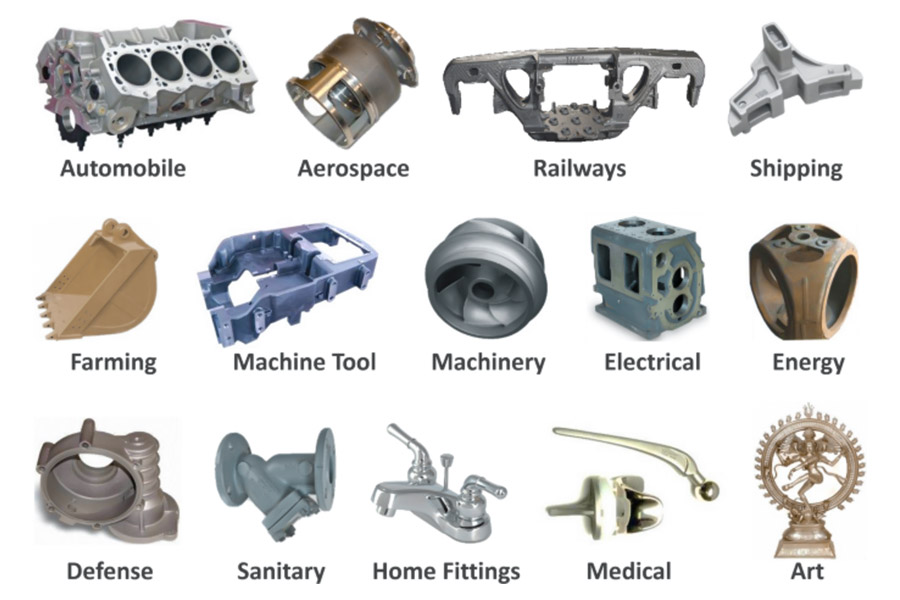

Typical Applications of Light Weight Aluminum Castings

In addition, the electrical sector frequently utilizes light weight aluminum spreadings for enclosures and real estates, promoting effective warm dissipation and enhancing safety. The durable goods field utilizes aluminum castings in products such as cookware and furnishings, where aesthetic appeals and functionality are vital.

The marine industry relies on light weight aluminum spreadings for parts that withstand harsh environments, such as boat hulls and fittings. Overall, aluminum spreadings offer a wide range of functions, showcasing their flexibility and important duty in modern production procedures.

Various Casting Approaches Clarified

Comprehending the different casting approaches is vital for picking the suitable method for light weight aluminum spreadings. Two popular methods, sand spreading and die spreading, offer distinctive benefits and applications. Each method's unique features influence the end product's quality and viability for particular usages.

Sand Spreading Process

While various casting techniques exist, sand casting remains among one of the most widely utilized techniques due to its adaptability and cost-effectiveness. This process includes producing a mold from a blend of sand and a binding representative, which forms the tooth cavity into which molten light weight aluminum is put. The sand mold can be conveniently formed and reused, permitting the production of intricate geometries. Once the light weight aluminum solidifies, the mold and mildew is broken away, disclosing the cast component. Sand casting is specifically appropriate for low to tool manufacturing volumes, making it perfect for customized elements. Its flexibility to different dimensions and forms, paired with the capacity to fit intricate layouts, even more enhances its appeal in different industries.

Pass Away Casting Techniques

Die spreading stands for an unique approach in the field of light weight aluminum spreading techniques, providing high accuracy and performance for automation. This approach includes requiring liquified light weight aluminum right into a mold under high stress, ensuring a high-quality surface and tight tolerances. There are two main sorts of die spreading: warm chamber and cool chamber. Warm chamber die casting appropriates for low melting factor alloys and permits quick production cycles. In contrast, chilly chamber pass away spreading is made use of for materials with greater melting factors, requiring the aluminum to be ladled into the chamber. Both methods make it possible for the production of complex shapes and elaborate styles, making pass away casting a popular choice for industries such as automobile, aerospace, and consumer products.

Benefits of Utilizing Light Weight Aluminum Castings

Many advantages make light weight aluminum spreadings a preferred selection across numerous industries. To start with, aluminum's lightweight nature significantly decreases the overall weight of products, boosting their effectiveness and performance. On top of that, aluminum castings show exceptional corrosion resistance, which extends item life expectancy and reduces upkeep expenses. The product's high thermal and electrical conductivity also makes it perfect for applications in automotive and electronics sectors.

Additionally, aluminum spreadings can be created with complex layouts, allowing makers to produce intricate forms that fulfill certain needs. This convenience not just supports ingenious designs yet also minimizes the demand for additional machining processes, saving time and resources. Light weight aluminum's recyclability lines up with sustainability objectives, appealing to environmentally aware businesses. Jointly, these benefits placement aluminum spreadings as a remarkable remedy for a variety of applications, making certain toughness, performance, and cost-effectiveness in today's open market.

Services Offered by Light Weight Aluminum Spreading Manufacturers

Additionally, they typically offer numerous casting methods, such as sand casting, die spreading, and investment spreading, each matched for different job demands. Quality assurance is an additional critical solution, with suppliers implementing rigorous screening and assessment protocols to guarantee that spreadings satisfy sector requirements.

Aluminum casting companies typically assist with finishing services, including machining, surface treatment, and finish, boosting the last item's resilience and aesthetic charm. They may provide logistical assistance, assuring timely distribution and effective supply chain administration to satisfy customer target dates.

Tips for Picking the Right Light Weight Aluminum Spreading Companion

Choosing the best aluminum casting partner can greatly affect the success of a job (Wisconsin Aluminum Foundry). To assure compatibility, business need to initially assess the companion's industry experience and technical proficiency. A company with a strong background in specific applications can supply cutting-edge options and valuable insights

Next, it is very important to review the high quality control procedures in area. A reliable companion will adhere to rigorous high quality standards and provide qualifications where suitable. Additionally, assessing previous projects and client testimonials can use a more clear understanding of the companion's capabilities and dependability.

Cost-effectiveness is additionally necessary; however, it ought to not endanger high quality. Firms need to look for a balance in between expense and the level of service given. Open communication and responsiveness are important qualities. A partner that focuses on collaboration cultivates a productive working partnership, inevitably resulting in Wisconsin Aluminum Foundry successful task end results.

Regularly Asked Concerns

Can Light Weight Aluminum Castings Be Fixed if Harmed?

Yes, light weight aluminum spreadings can be repaired if damaged. Wisconsin Aluminum Foundry. Techniques such as welding, brazing, or adhesive bonding are typically used, depending upon the degree of the damages and the particular demands of the repair process

Exactly How Do Aluminum Castings Compare to Various Other Metals?

Light weight aluminum castings are lighter, corrosion-resistant, and extra flexible compared to other metals like steel or iron. Their outstanding thermal conductivity and recyclability make them a favored option in different markets, enhancing convenience and efficiency.

What Is the Life-span of Light Weight Aluminum Castings?

The life expectancy of aluminum castings generally ranges from 10 to 50 years, relying on ecological problems, alloy composition, and application. Correct upkeep and protective steps can considerably boost their resilience and durability in various setups.

Are Light Weight Aluminum Castings Recyclable?

Yes, aluminum spreadings are recyclable. They can be melted down and repurposed without losing their fundamental residential or commercial properties, making them an eco-friendly option. This recycling procedure adds to sustainability and lowers the need for new aluminum manufacturing.

How Do I Preserve Aluminum Castings?

To keep light weight aluminum castings, one should frequently clean them to get rid of dust and oxidation, use safety coverings to prevent rust, and check for damage to ensure longevity and architectural stability in various applications.

The convenience of light weight aluminum spreadings enables their extensive use throughout numerous industries. Understanding the numerous casting techniques is necessary for choosing the proper method for aluminum spreadings. Die spreading represents an unique approach in the area of aluminum spreading strategies, providing high accuracy and efficiency for mass production. Countless advantages make light weight aluminum castings a favored option throughout different industries. Furthermore, they commonly offer different casting approaches, such as sand casting, pass away spreading, and investment casting, each fit for various job needs.